Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() February 06, 2024

February 06, 2024

| Type of forming | Roller forming machine |

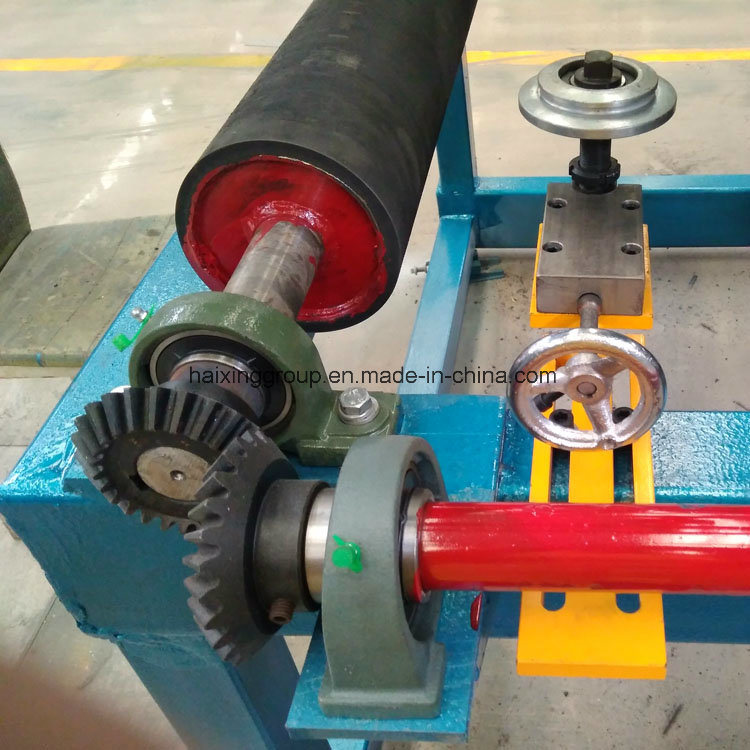

| Shaft diamete | 70mm(solid shaft) |

| Material of roller | No.45 steel, heat treatment |

| Frame structure | 350# H steel. |

| Chain | 1 inch |

| Froming stands | 16 rows and 20 rows |

| Speed of forming | 6m/min synchronies with panel machine |

| Type of synchronies | electrical synchronies |

| Driven power | 7.5 kw |

| Cutting power | 3.0 kw |

| Installation instruction | two parts |

| Size of forming machine | 8000×1600×1300mm |

| Weight of forming machine | About 4.5t |

| roller diameter | 150 mm |

| thickness of composite rubber layer | 10mm |

| hardness of composite rubber layer | 60 |

| numbers of pump | 4 sets (top and bottom each 2) |

| Driven power | 0.37 Kw |

| Flow volume of glue | 0~0.4 kg per pump |

| type of flow volume control | Change frequency |

| Scale of glue: (white): (Black) | 1:5 |

| speed of spreading | 80 times/min |

| driven power | 0.5kw ×3 |

| Grooving | according to the design requirement |

| depth of groove | 0.5~1.0mm |

| type of shearing | Electrical |

| numbers of shear | 2 sets (top and bottom each one) |

| Driven power | 0.75KW |

| Electrical Voltage | 380V/3Ph/50Hz |

| Type of controlling | PLC (Delta Taiwan) |

| Transducer | 0.4KW (Made in China) |

The above is the EPS Sandwich panel Making Machine Production Line we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.